Testing Methods

Diffraction Measurements with Electric Fields

Critus diffraction cells are designed for use in conjunction with lab-based or synchrotron XRD instrumentation. Studies can vary from simply taking diffraction patterns at a set temperature and electric field, to full hardware synchronized time-resolved measurements under cyclic electric field loading. Critus cells are also equipped with precision electrical and mechanical property measurement systems and can operate as stand-alone devices.

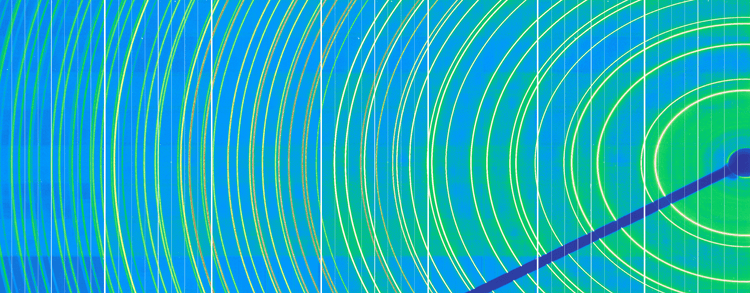

Why use these cells? In situ diffraction data tells us about the structural response of a material to an applied electric field. For example, there are several known mechanisms by which piezoelectric materials respond at different points in the polarization and strain hysteresis, including lattice strain, domain volume fraction changes and phase transformations. All of these mechanisms are resolvable using diffraction measurements. During the development of new material system, quantification of these mechanisms is critical.

Methods of Usage

Here, we simply highlight a few examples of how the cells can be used. However, we hope that the user community also comes up with new and inventive ways of using our devices for the progression of scientific understanding in electrical and electro-mechanical materials.

Static Field and Temperature

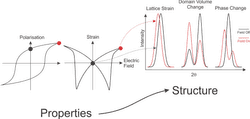

This is likely the most basic type of in situ experiment that can be performed and is an extremely powerful tool for understanding the underlying structural mechanisms of material response. With a sample loaded in the cell, the temperature of interest is first set via the browser-based interface. An initial diffraction pattern is collected from the sample. Then a single electric field value is set, it may be above the coercive field in the case of a ferroelectric, and another diffraction pattern is collected. This structural information can then be used to directly ascertain the electric-field-induced structural change in the material.

Structural Change after Electric Field Cycle

As Critus diffraction cells also collect macroscopic electrical and electro-mechanical property data, changes in structure due to an electric field cycle can be observed and directly correlated to those properties. Here, an initial diffraction pattern is collected. Then, an electric-field waveform is applied to the sample with the macroscopic property data collected. On completion, an additional diffraction pattern is collected and compared with the original. In this way, the material property variations measured can be directly correlated to structural changes of the material. This type of data collection is ideally suited to studying processes such as poling treatments and fatigue degredation.

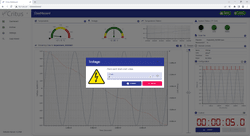

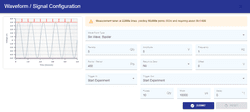

Time-Resolved Diffraction Measurements

This is an advanced use of Critus electric field cells. The user interface of the waveform setup also has embedded hardware synchronisation triggering options for the Critus cell to operate as either a master or slave to other instrumentation. For an XRD instrument, the "Trigger Out" option can be used for example to trigger an XRD detector system to collect diffraction data at specific points within the applied electric field cycle. In this way, the real-time structural variations can be directly correlated to the simultaneously collected macroscopic property data. Time-resolved experiments could be performed both in single-shot mode, or stroboscopic mode, where diffraction statistics can be built up over many cycles of a repetitive electric-field waveform. This type of data collection is most likely performed at synchrotron sources, where synchronisation to other elements of the data acquisition system is required. It also offers the most thorough insight into the structure-property relationships of electrical and electro-mechanical response.

Products

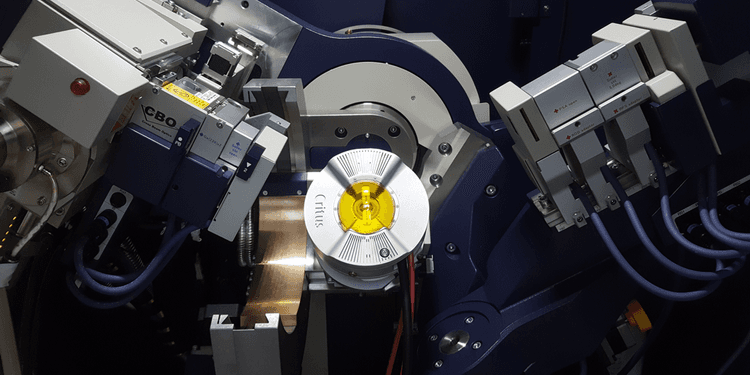

Bulk Reflection Geometry

The Reflection Geometry system allows electric fields of ±5kV to be applied to bulk materials while conducting XRD measurements from a surface. Ideal for electro-ceramic and single crystal research in laboratory or synchrotron x-ray systems. Electrical current and displacements sensors are packaged within the unit allowing simultaneous strain and polarization measurements.

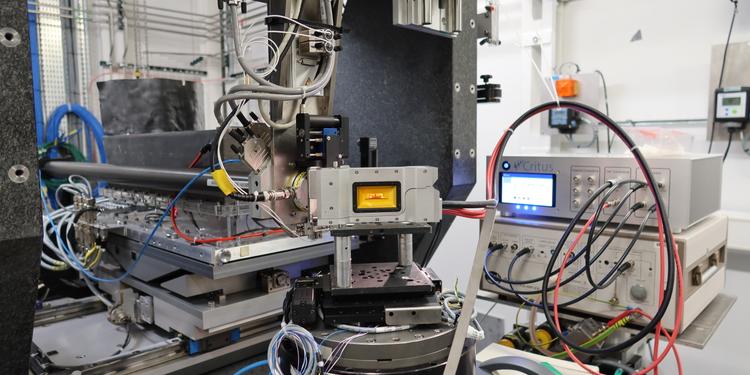

Bulk Transmission Geometry

Working with high-energy x-rays offers some advantages in the study of bulk electro-mechanical materials. The Transmission Geometry system is ideally suited for use at high-energy synchrotron x-ray beamlines or lab sources with higher energy targets such as Ag or Mo. Precise polarization and strain measurements can be obtained in-situ at voltages up to ±7.5 kV.